@DylanRose wrote:

Well i'm finally getting to the point where I almost feel i might, possibly, understand some of the settings, to some degree, and can sort of predict, in some cases, the feeds, speeds, and everything else without destroying the material or the blade. Sort of. So that's progress! ha

My question is about parts that have some considerable clearing as well as some fine detail in some areas as well. I picked up a few smaller bits (1/16, 1/32 & 1/64) and have had a good time experimenting with each, but one hurdle i'm facing is that is I have a job that had both lots of clearing as well as fine detail, I can do a roughing pass with the 1/8 and a finishing pass with a 1/16 or smaller, but it still has to cover the entire surface of the stock which is really time consuming.

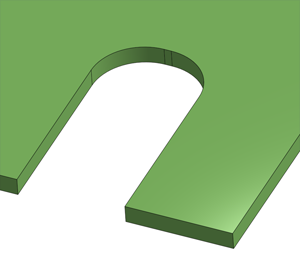

So say I've got a part with some internal corners and the roughing pass takes care of the general shape:

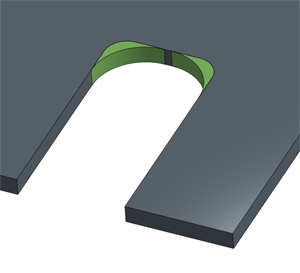

Then I want to finish off the corners with a smaller 1/16 bit to sharpen out the edges:

What I can't seem to figure out is how to make sure the finishing pass doesn't go back and cover the entire surface again, wasting a lot of time on the flat areas and other edges that the 1/8 bit can handle. Is there something obvious i'm missing in Meshcam or is this just a limitation of the software? Or a limitation of CAM in general?

Posts: 3

Participants: 3